Stats:

Engine:

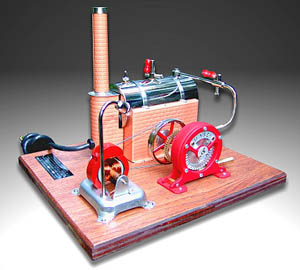

Jensen Steam Turbine #95G

Boiler: Cheddar Plover vertical

Fuel: Propane/Butane mix

Chassis: Kyosho Nitro Blizzard

Operating pressure: 20psi

Run time: 15 mins

Boiler: Cheddar Plover vertical

Fuel: Propane/Butane mix

Chassis: Kyosho Nitro Blizzard

Operating pressure: 20psi

Run time: 15 mins

UPDATE: Step by Step instructions on instructables! Click Here!

|

Got Turbine? So what do you do after you've made a bunch of steam powered r/c tanks? Well you try making a steam turbine tank of course! Making a steam turbine r/c machine has sort of been one of my Holy Grails, but there are many issues with steam turbines, that made it difficult for me to tackle on the project. The issues with steam turbines: 1) Unlike steam piston engines, steam turbines don't have much initial torque, and need to spin up to super high rpm's for maximum torque. 2) Steam turbines uses up steam much faster than steam piston engines, the boiler must be able to produce steam very fast. 3) Turbines only spin on way, which means no reverse, or need a reversing clutch. 4) Cost. Nothing about steam is cheap, and there isn't really a choice when it comes to off the shelf steam turbines... this is where Jensen comes into the picture. |

The Jensen Turbine

|

|

Jensen Steam Engines: Jensen has been around for over 75 years, making amazing toy & collector live steam engines. About a year ago, they saw my work, loved what I've been doing with live steam, and generously donated engines to make whatever I liked. How freakin' cool is that? the result was the Jensen Steam Armatron, the first stationary machine that I've hacked together. So many months passed, and they contacted me again. They've got the model #95G steam turbine, and agreed to sell me a couple of them at cost. I must admit that I probably would never have attempted this project if it wasn't for Jensen twisting my arm. Turbines just sounded like more trouble than what it is worth, and I just did not have any confidence on being able to pull this one off. The lack of torque, need vast amount of steam, just doesn't sound like a likely project for any r/c vehicle. However, once I got one in my hands, a whole new world opened up. The #95 turbine's craftsmanship is top notch, full ball bearings, and screams like a demon dentist. The first time that I tested it out on an air compressor, I think my ear to ear grin lasted days. What I'm sure is obnoxious & high pitch screech to my poor neighbors, is music to my ears. And to my surprise, it had much more torque than I anticipated! The amazing design of the turbine, was conceived by a well known miniature turbine maker, Mr. Karsten. Working closely with Jensen, the #95G is one little screaming machine. You have to give it to Jensen, for taking a bold step in coming out with something completely different, after making pretty much the same engines for the past 75 years. |

One of my absolute favorite

live-steam models, the Karsten V-6 power

plant, w/ dynamo and able to generate enough electricity for a couple

of

small lamps

|

|

The

details:

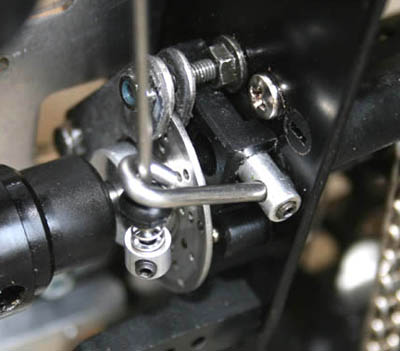

For the choice of chassis, I needed something with a clutch, since turbines can only spin in one direction. Since I don't have any machining skills, I rely on things that I can find cheap on ebay :) I picked an used Kyosho Nitro Blizzard, since I am a sucker for vehicles with treads. This is the first time that I've used a nitro chassis & reversing clutch, since previous steam machines that I've made all had direct reverse with the steam piston engines. The steering is achieved through a differential, with brakes for each side. This braking system is a bit different than the Tamiya tank chassis that I've used before, and ended up spending quite a few nights trying to get the steering to work correctly. For the boiler, I used a Cheddar Plover vertical. It can pump out & sustain a constant supply of steam, and with the vertical layout, I was able to fit everything onto the chassis, with room to spare for a big disposable gas tank (camping propane/butane mix) In the he first initial test runs, it had many issues. The treads were made for snow, therefore it had many paddles which put a little strain for the turbine to torque over, and made the drive quite bouncy. I cut the paddle treads down by half, and it helped a bit, although it is still a bit jerky as the tank needs to torque over each tread paddle. For R/C it is a standard 2 channel, one for steering, and one for the forward and reverse clutch. The final turbine tank took me by surprise, it can climb rather well (see video below). I didn't expect a turbine could easily carry its own weight, let alone be the best climbing steam tank in my fleet! Got to give it to Karsten & Jensen for such a torquey turbine. It only needs 20psi to started crawling over just about anything :)  |

Kyosho blizzard brakes for skid steering Cheddar Plover boiler

|

VIDEO:

Updated video with reduced bounciness

Back to Crabfu SteamWorks